It has advantages of fast filling speed, high precision in liquid level. Adopt Siemens automatic controlling system, realizing trinity of the machines, and control the washing, filling and capping process and realize that it only starts to filling when there is a bottle, otherwise it will stop filling and no broken bottles. The filling process is cleaner and pure due to it’s twice vacuum of bottles, and more stable because of isobaric filling operation. Using vacuum pump and CO2 preparing pressure to realize a second vacuum ensure no air and bacteria in the bottle, guarantee the filling quality and warranty quality time. Filling cylinder braces use worm-gear box going up and down to satisfy bottles of different height. Float switches in the filling cylinder ensure a smooth liquid inlet. Therefore, this machine is the best ideal choice for beer or beverage factories.

Summary

The main properties of machine: rational design, easy operation, safety device, plate easy cleaning, the height is adjustable.

The machine can be divided into seven parts: a. rinsing part, b. filling part c. Operation platform d. capping part e. bottle transmission part f. pipe system g. liquor level control, liquid main pipe.

Advantages

1.It can fill 1000-1500 BPH and be suitable for small breweries whose output is 1-5 tons.

2.The 8-8-3 unit beer filling machine is all-mechanical transmission, which basically reaches zero failure rate.

3.After two times of vacuuming and carbon dioxide flush, the filling is completely isostatic.The external filling valve is on the outside of the beer tank. Compare this with the internal filling valve in the beer tank, external filling vale will not touch the beer and avoid the beer pollution. Otherwise, the external valve opens and closes through mechanical pressure, it can realize real isobaric filling and reduce the generation of air bubbles.

4.About capping,we replaced the pneumatic cover with a mechanical cover,the quality and stability of the gland are improved.

5.All the wires are on the top of machine,this improves the security of machine.

A. washing part

B. filling part

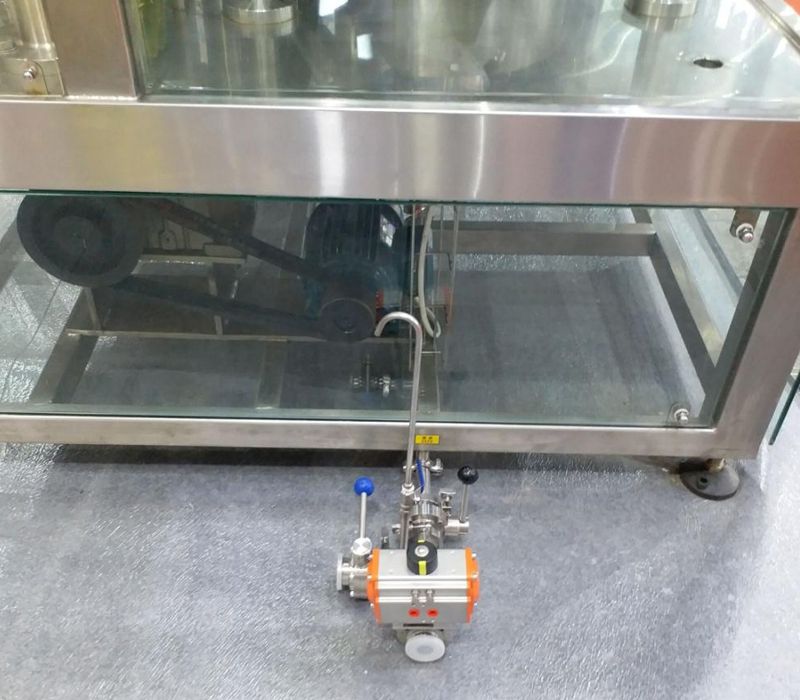

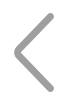

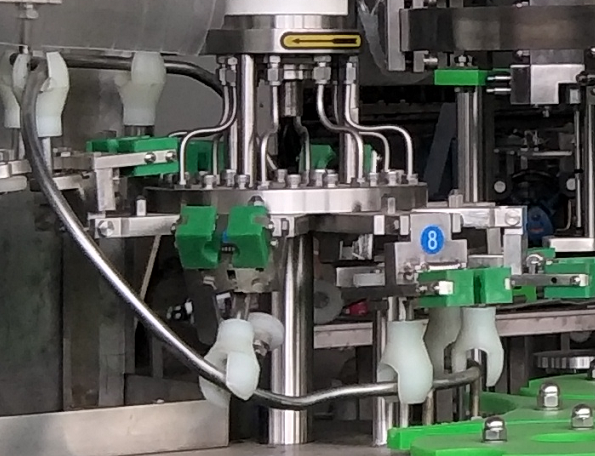

Filling machine are made up of beer pipe, rotating cylinder bearing base, filling cylinder fulcrum loop, filling cylinder, filling valve, filling cylinder pipe, control loop device, ascending device, the distributor, height adjusting control, cleaning glass, stimulating bubble arm, vacuum system, etc.

C. capping part

The capping machine is composed of hopper, slide rail, top-cap part, lifter, and turn-stop column.

All conform to the standard of the crown cover only height diameter in order to insure the normal operation of capping machine work, the crown cover as much as possible should be stored in dry room.

Capping Machine is transmitted by the gear to spindle and platform, then to platform seat; rotary bearings.Gland plunger up and down movement is achieved through the gland cam; capping cam is fixed.

Crown cover passes the hopper in storage into a blender and then sent to the head of gland plunger.